To avoid unexpected breakdowns and expensive repairs, companies with a large fleet of vehicles should regularly check their operating fluids.

Portable particle counters offer fleet operators including waste disposal companies, construction companies etc. the opportunity to ensure that their fleet management remains efficient by way of preventative maintenance measures. During preventive maintenance, damage to hydraulic components and filters can be detected at an early stage with the assistance of particle analysis. Observing the particle analysis enables a trend to be identified and thus making it easier to detect a change in the particle counts. This, in turn, allows service and or repairs to be planned and unexpected vehicle/component breakdowns can be prevented. If the contamination of the monitored fluids is known, the operator can react based on the particle results and intervene in time before complete failure of the component or entire system. Furthermore, scheduled oil change intervals or similar scheduled maintenance procedures can be adapted to the actual condition of the machines/systems and premature or unnecessary work can be excluded.

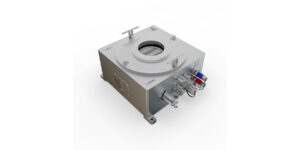

The robust, compact design along with its simple, user-friendly operation makes the PAMAS S40 portable particle counting system the optimum instrument for this type of application. Compared to measurements in a laboratory setting, measurements in the field not only offers the user cost and time saving aspects, but also eliminates the need for sample preparation. Situations arising from sample storage, including sedimentation and agglomeration, are factors that do not need to be considered as the sample liquid is not transported to the laboratory and therefore does not have to be decanted and stored.

Fleet managers also appreciate the ability to operate the instrument independently of mains power via the built-in rechargeable battery. Samples can be taken from any sample container or even directly from a vehicle’s hydraulic system. Another advantage is the low dead volume and automatic flow control of the PAMAS S40 instrument. This makes it possible to achieve an accurate, reliable measurement result even with the smallest sample volume. For clear data management, PAMAS offers the PAMAS CMDM software. With this software, the measurement results can be clearly organized, retrieved, and stored individually for each vehicle.