People say, and genuinely believe, that beer is the favourite drink in Germany. Also, beer is the global market leader of alcoholic beverages. For centuries, breweries have had to fulfil the highest of quality standards. In addition to the brewing ingredients, the manufacturing process is strictly monitored too. An important step in beer production is filtration. Using laser particle counters, beer filtration can be accurately monitored and continuously optimized.

Since the beginning of 2020, the Badische Staatsbrauerei Rothaus, located in the Black Forest, uses a PAMAS OLS50P online particle counter for filtration control. Towards the end of the brewing process, yeast is removed from the wheat beer using kieselguhr. The PAMAS OLS50P will detect a possible breakthrough of both yeast and filtration material and provide further insights to the filtration process. The particle counting process provides an ideal addition to the already used turbidimetry, as it gives a faster indication and further information to the particle’s quantity and size.

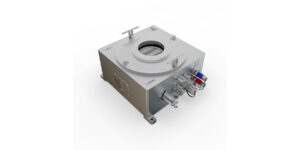

The particle counter had to be configured correctly to fulfil the breweries application requirements. As an example, sapphire glass was installed into the measuring cell of the sensor instead of the standard quartz glass. This reason for this was that the filtration plant is regularly cleaned with sodium hydroxide solution at a temperature of 80°C. The change in the composition of the measuring cell glass is to prevent possible glass corrosion.

The beer has a temperature of between 3–5 °C. To avoid the risk of condensation within the instrument, the housing has been equipped with two additional sockets and connected to the in-house pressurised air system. The diagonal perfusion effectively prevents the formation of condensation water. A great example how PAMAS adapts a standard solution to face a potential environmental issue.

Do you also wish to integrate a particle counter into your manufacturing process to increase productivity but are not sure whether it’s possible due to certain specifications or limitations? Get in touch with PAMAS to discuss your application and operational requirements. We would love to hear from you!

Photos © Rothaus und PAMAS