Welcome!

From now on, we will provide you regularly technical background informations on automatic particle measurement, application reports from the field, helpful product informations and other interesting topics and events around particle counters and us – the PAMAS company.

Let´s start with THE IMPORTANCE OF PARTICLE COUNTING:

Why is the degree of contamination of liquids so important?

Liquid purity plays an important role in a variety of industries for a diversity of reasons. Frequently, the particles in the micrometer range that are not visible to the human eye are particularly critical. Among other things, this is the case with

- hydraulic systems

- Industrial gears

- turbines

- transformers

- component purity for example in the automotive industry and medical technology

- water treatment

- quality control of pharmaceuticals

The first three examples are mainly concerned with the early detection of abrasion damage or beginning oil wear and filter monitoring. In the other areas, the purity of the liquid or the product and compliance with specified limit values is of central importance. An increased level of pollution can lead to safety risks, environmental and health hazards as well as quality defects.

How can you determine if the liquid is contaminated with particles?

As already mentioned, the contamination that is critical for an application cannot usually be perceived to the naked eye. Different methods are available for measuring particles in the invisible area.

Classic processes such as gravimetry or microscopic enumeration are time consuming and

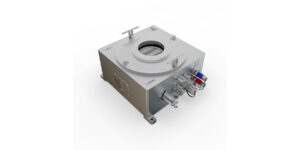

in certain circumstances subjective. The fastest and most objective analysis is measurement using laser-optical particle counters, which automatically count the pollution particles using a flow measuring cell and classify them according to their size.

Founded in 1992, PAMAS develops, manufactures, distributes and services laser particle counters to measure particulate contamination in liquids. We cover the entire spectrum from online and laboratory devices to portable models.