For optimal performance and a long service life of lithium-ion batteries, the optimal operating temperature of the battery has a decisive role. Effective thermal management is, therefore, fundamental and can tip the scales in racing. In this case, a synthetic PAO oil is used for thermal management in Formula 1.

The optimal operating temperature for lithium-ion batteries is between 44 and 46 degrees Celsius. If these temperatures fall outside this range, the performance, and service life of the batteries can be negatively affected.

The PAO oil in the circuit acts as a medium to stabilise the overall temperature throughout the battery by means of thermal conduction fluid circulation. It has a very high insulation resistance factor so not to impede the electrical performance of the battery.

Charging and discharging of the battery causes accumulative wear, and the process can lead to minute particles being suspended within the fluid. These particles can build up and create conductive bridges that will cause failure.

To ensure optimal battery performance, the oil must be filtered into the closed circuit of the battery and then the battery cells are flushed thoroughly.

The battery flushing rig was designed by our system Integrators, Reynolds Contamination Control Ltd, to remove contaminants, qualify the cleanliness standard of the battery and fluid to AS4059F <cpc4, and provide full traceability to ISO 11171:2022.

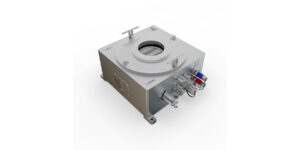

In this application, the PAMAS OLS50P online particle counter is used as part of the Reynolds flushing rig for checking the cleanliness of the oil during the filling & cleaning process.

More information about the PAMAS OLS50P here.